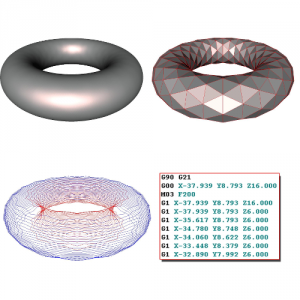

From 3D models to 3D prints: an overview of the processing pipeline

Lecturer: Jonàs Martínez, Marco Livesu

Due to the wide diffusion of 3D printing technologies, geometric algorithms for Additive Manufacturing (AM) are being invented at an impressive speed. Each single step along the processing pipeline that prepares the 3D model for fabrication can now count on dozens of methods, that analyse and optimize geometry and machine instructions for various objectives. We provide a classification of this huge state of the art, and discuss the relation between each single algorithm and a list of desirable objectives during model preparation – a process globally refereed to as Process Planning. We broadly categorize AM technologies to explicitly relate classes of devices and supported features. Finally, we provide an analysis of the state of the art while discussing open and challenging problems from both an academic and an industrial perspective.

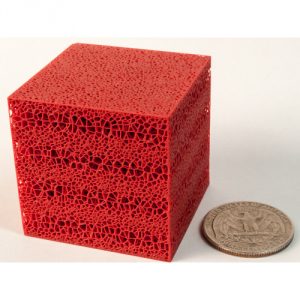

Procedural and stochastic microstructures for functional fabrication

Lecturer: Jonàs Martínez

Additive Manufacturing (AM) technologies are now capable of fabricating microstructures at the scale of microns, therefore enabling to precise control of the macroscopic physical behavior. This control empowers a wide range of industrial applications by bringing high-performance customized materials. We present a set of procedural, stochastic, and fabricable microstructures, with a controlled macroscopic physical behavior. The presented microstructures will computationally scale with future AM technologies, and afford for free grading and embedding into objects.

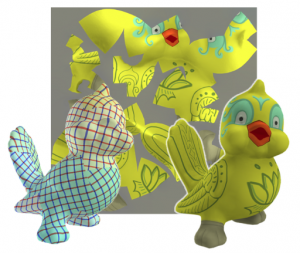

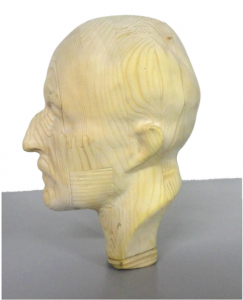

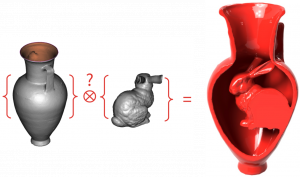

Fabrication-aware shape decomposition

Lecturer: Marco Livesu

Fabricating an object starting from a digital representation of it is a complex process that requires both geometric knowledge and manufacturing insight. Part of this complexity depends from the fact that each manufacturing technology imposes a number of geometric constraints that must be fulfilled to be able to create physical replicas of our digital shapes. Some of these constraints are hard (e.g. size constraints imposed by the machine at hand) while some others can be relaxed (e.g. control surface orientation to reduce overhangs). An effective way to address both hard and soft constraints consists in splitting a complex object into smaller pieces, such that each piece endows strong geometric properties which are beneficial for the fabrication technology at hand. In this talk I will present some of the results of our latest research in the field. Both additive and subtractive manufacturing technologies will be considered.

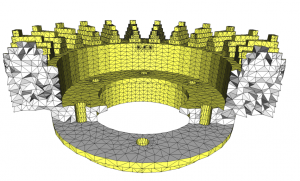

Simulating additive manufacturing: a meshing perspective

Lecturer: Marco Livesu

Accurately simulating Additive Manufacturing (AM) processes is useful to predict printing failures and understand the process without wasting precious resources, both in terms of time ad material. In AM the object to be fabricated is first decomposed into a set of slices aligned with the build direction, and then printed by depositing or solidifying material one layer on top of the other. Since the domain of the simulation evolves in time, to guarantee accurate simulations it is necessary to encode the temporal evolution of the print in the simulation mesh. In this talk I will introduce slice2mesh: a meshing software capable of turning a sliced object into a volumetric mesh that we developed at CNR IMATI. slice2mesh inputs a set of slices and produces a tetrahedral mesh that endows each slice in its connectivity. An accurate representation of the simulation domain at any time during the print can therefore be easily obtained by filtering out the slices that have not been processed yet. Working in slice space allows us to esily handle extremely complex shapes, support structures and infills. Furthermore, the user can trade accuracy for simplicity by producing approximate simulation domains obtained by filtering the object in the slice space.

Appearance representation, editing and reproduction

Lecturer: Fabio Pellacini

In this short course, we will introduce the basic of appearance representation, editing and reproduction with a focus on materials that can be printed accurately. We will cover the basic of BRDFs, BSSDFRs and volumetric scattering, the methods for their design and a few techniques used in their physical reproduction.

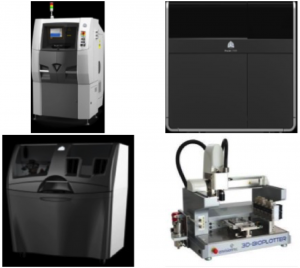

An overview of additive manufacturing hardware

Lecturer: Bernd Bickel

What techniques and materials are out there, what are their pros and cons, and what are the manufacturing limitations of each of them.

State of the Art on Stylized Fabrication

Lecturers: Bernd Bickel and Luigi Malomo

Abstract: Digital fabrication devices are powerful tools for creating tangible reproductions of 3D digital models. Most available printing technologies aim at producing an accurate copy of a 3D shape. However, fabrication technologies can also be used to create a stylistic representation of a digital shape. We refer to this class of methods as “stylized fabrication methods.” These methods abstract geometric and physical features of a given shape to create an unconventional representation, to produce an optical illusion, or to devise a particular interaction with the fabricated model. In this state-of-the-art report, we classify and overview this broad and emerging class of approaches and also propose possible directions for future research.

(Beyond) 3D Printing: Geometry Processing for Fabricating Digital Objects based on reusable Molds

Lecturers: Bernd Bickel and Luigi Malomo

(course confirmed – more info coming soon)

Mesh processing tools for digital modeling and manufacturing

Lecturer: Marco Centin

The preservation of the quality of 3D data along the possibly long chain from digital scanning to 3D model deployment is of paramount importance within an increasing number of advanced geometry design processes in the mesh domain, including digital fabrication. However, in many cases, model finalization is not a trivial task, especially when dealing with multiple dense meshes that are not watertight and may be generated by creative editing procedures such as partial model combinations, customized hollowing, free-form escape holes, sectioning planes or other cutting surfaces. This evidences how non-trivial mesh composition and completion responding to quality preservation needs is still challenging in various demanding application contexts. In this talk I will explain a set of versatile mesh-processing techniques that simplify the finalization of a mesh model for 3D-printing applications.

Surface Parametrization

Lecturer: Marco Tarini

A parameterization of a surface can be viewed as a one-to-one mapping from a surface embedded in 3D to a suitable domain, typically a portion of the 2D plane (often but not necessarily, homeomorphic to a disk).

Constructing a parameterization for a given surface means mapping one surface into another.

This is one of the central to Geometry Processing because parameterizations have numerous applications, in computer graphics (primarily, texture mapping), and as a intermediate step for surface approximation, meshing or remeshing, morphing, inverse subdivision surfaces, repair of CAD models, printing, and many others. Barring special cases, the mapping cannot be expected preserve quantities such as lengths, angles or areas; in order to be useful in the end application, however, the mapping must strive to minimize the discrepancies, called “distortions”. In addition, it is often necessary to introduce cuts in the input surface in some suitable way, before the mapping into the required domain can be attempted; cuts is necessary both for topological reasons, when the input surface is not homeomorphic to the domain, and to reduce distortions. The purpose of this course is to give an overview of the many different ways of addressing these tasks.

DEMO session

Visit to the Advanced Prototyping LAB of the University of Brescia

The Advanced Prototyping Laboratory (LPA) is a University facility whose function is to make new technological solutions immediately available using different tools such as additive manufacturing machines, 3D scanners and software for process simulation and product optimization. The following machines are available at the LPA: ProX 100 (Metal), ProJet 2500 (Resin), ProJet 460 (Color Gypsum) and Bioplotter (Biocompatible Materials).